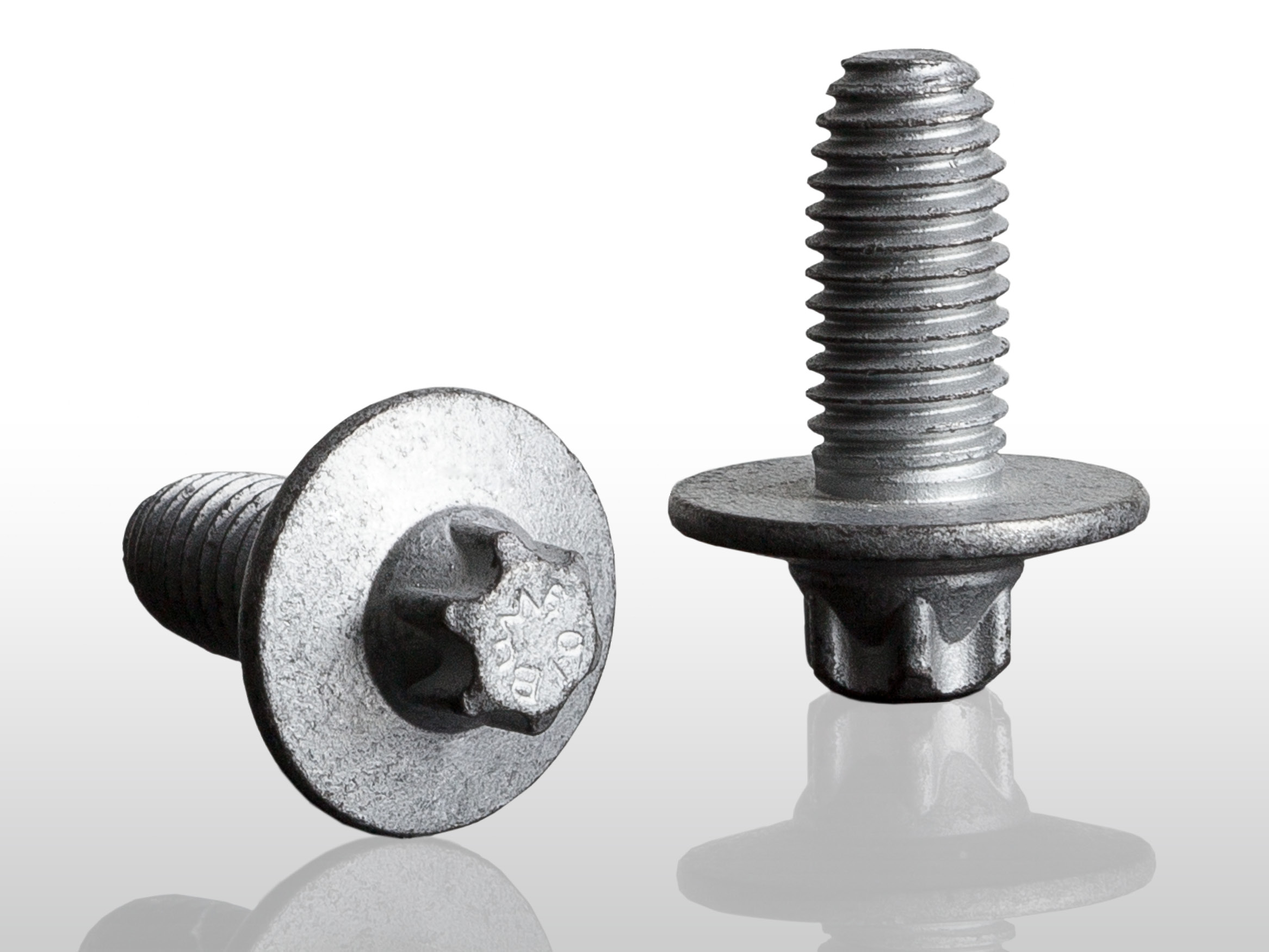

Direct Screwing in Metals

In direct screwing, fasteners generate a thread without cutting during the screw-in process.

The principle of non-cutting forming used here produces a thread with high load-bearing capacity due to the uninterrupted grain flow and strain-hardening of the material. Additional screw locking (e.g. to DIN 267-27/28) is therefore unnecessary.

The generated thread is a metric ISO thread, which is compatible with standard parts. Furthermore, the threads formed in this way are free of play and are self-locking. Thread-forming screws can be used in all ductile, i.e. plastically deformable materials.

Benefits

- Cost advantages through the elimination of thread cutting and through direct use in cast, drilled or punched holes

- Produces an uninterrupted grain flow and a thread with high load-bearing capacity by strain-hardening of the material

- Through the forming process of the thread, no interfering chips are created

- The thread geometries of all our direct screwing systems have a large tolerance range preventing angular errors when the screw is applied

- No play between the screw and its self-formed nut threads

- No threadlocker is required due to the associated self-locking effect

- Repeat screwing is possible

b&m Brands

b&m-FORM S®

Direct screwing system with shortened forming zone suited for all ductile metal materials

b&m Innovation

b&m-TIGHT®

Direct screwing system with integrated sealing function for aluminum-steel hybrid applications

b&m Innovation